Our Services

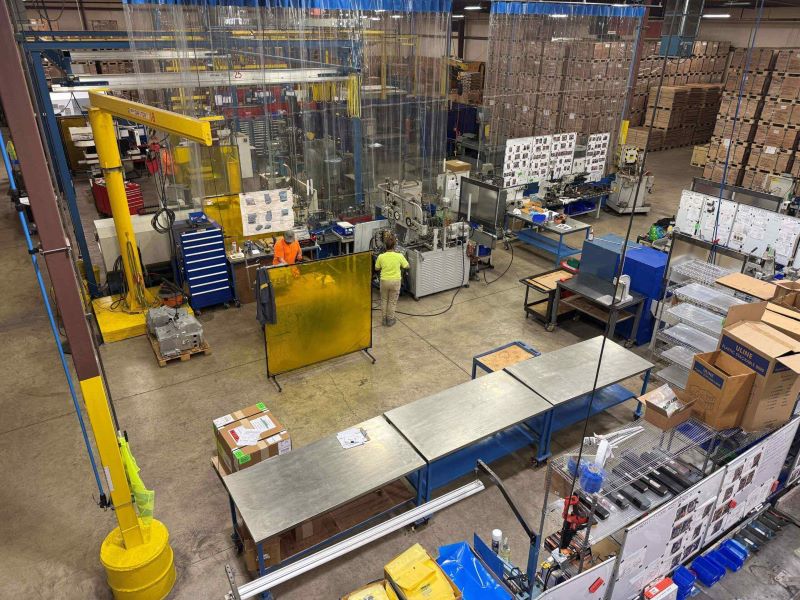

Our end-to-end manufacturing solutions are designed to meet your specifications. Backed by advanced manufacturing & testing, rigorous inspection, and expert professionals, we ensure your operations remain uncompromised.

Our end-to-end manufacturing solutions are designed to meet your specifications. Backed by advanced manufacturing & testing, rigorous inspection, and expert professionals, we ensure your operations remain uncompromised.

Our technical cleanliness clean room laboratory is outfitted with leading-edge equipment and run by experienced and highly skilled scientists and technicians.

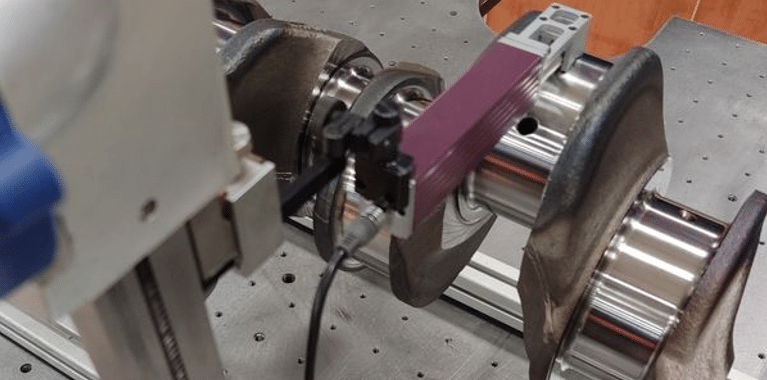

Surface finish testing involves measuring the texture and smoothness of a material’s surface to ensure it meets required specifications.

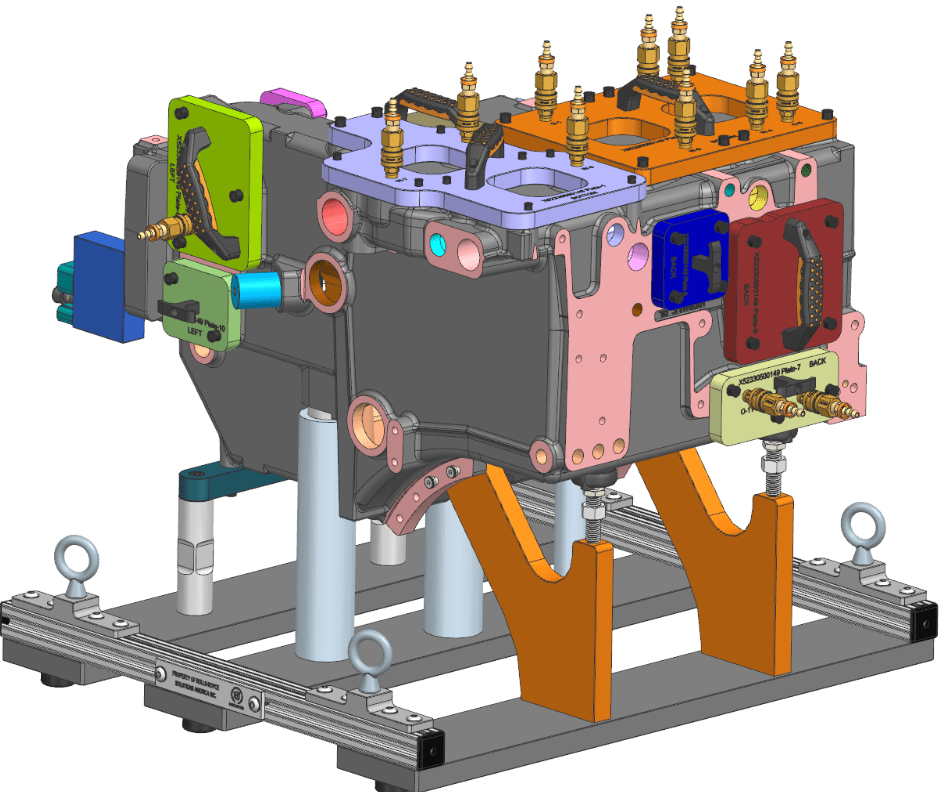

Ensure the safety and reliability of your systems with our precision leak testing and pressure testing services. Our skilled technicians certify hundreds of thousands of critical components each year. If needed, our in-house team can design and manufacture custom fixtures and test rigs to deliver precise, dependable results to your specifications and in conformance with industry standards.

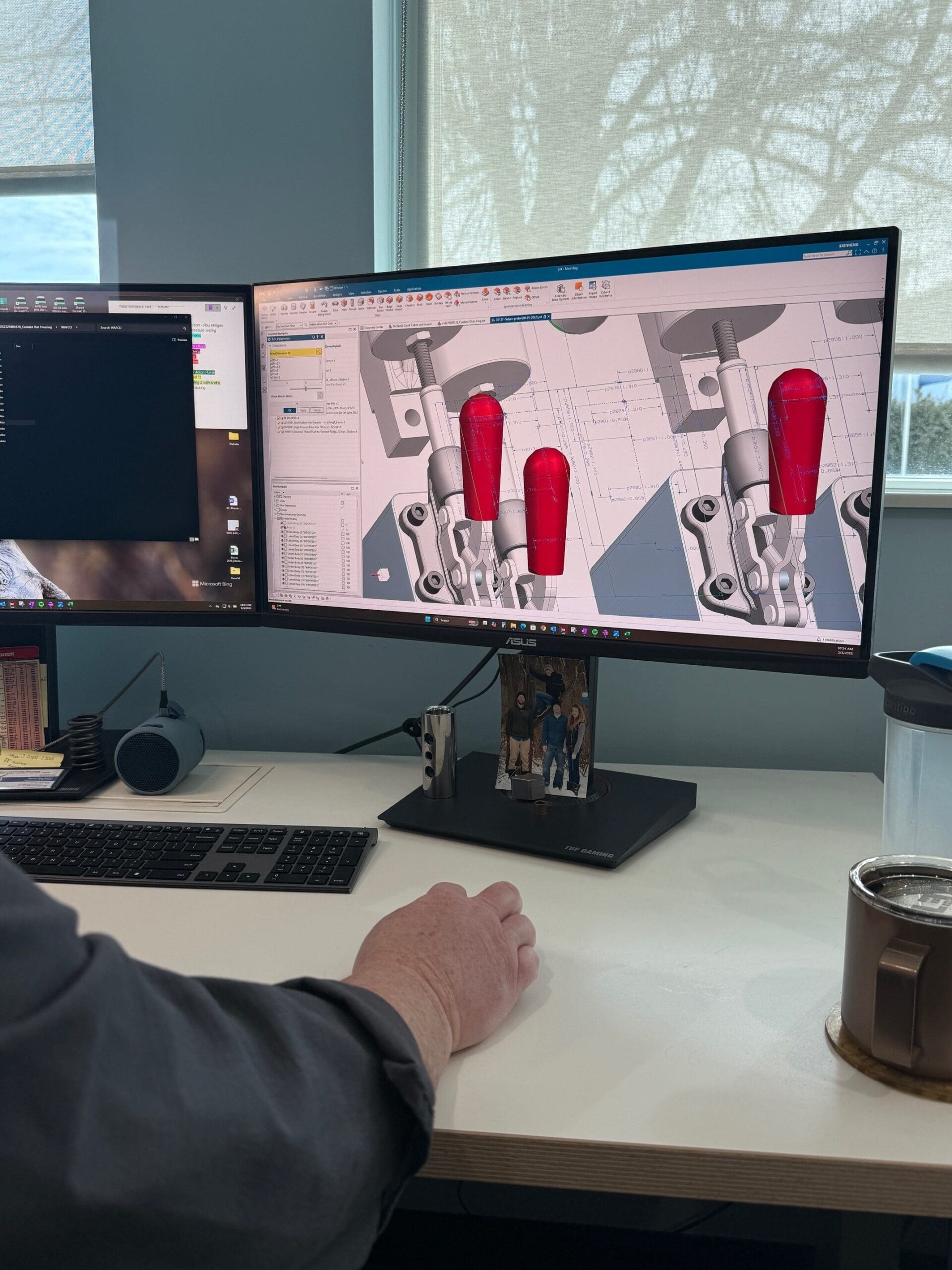

Using NX Design software (CAD), our engineering group can quickly design a wide range of testing equipment, fixtures, unique tooling or fabrications necessary for today’s manufacturing needs.

Our manufacturing group offers a wide range of services from design, manufacturing, fixturing, assembly, pressure testing and CMM inspection services. We often develop outlines for part traceability and work instructions for assembly and testing processes with step-by-step visual reference.

Our Prototype-to-Production Machining services cover both 3 and 5-axis machining, handling everything from prototype development to large-scale production. We provide precise machining for a range of components, ensuring consistency and quality throughout the process.

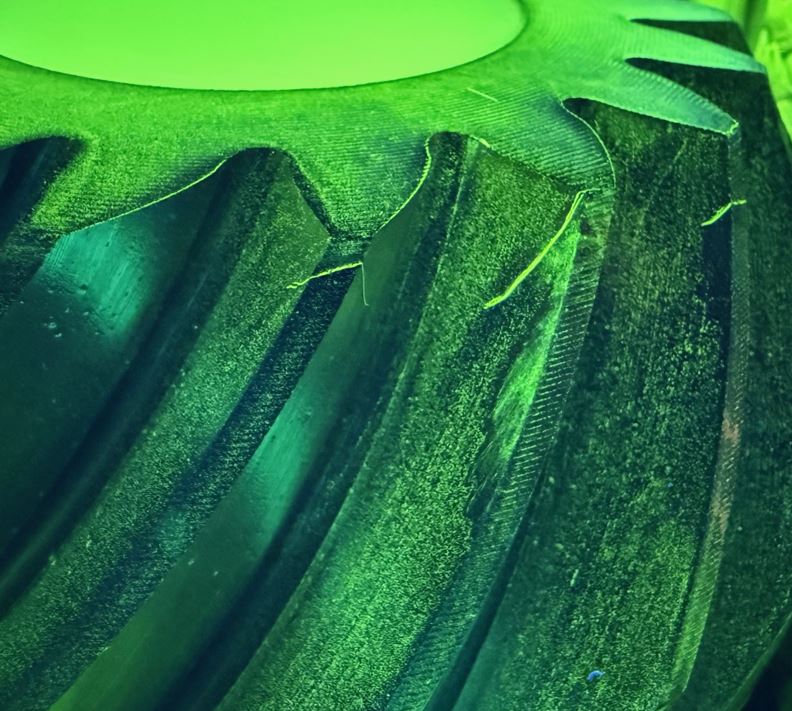

Liquid Penetrant Testing (PT) is a non-destructive testing method for detecting defects that are open to the surface in non-porous materials, such as metals, plastics, and ceramics. We have visible penetrant as well as fluorescent penetrant capabilities.

Magnetic Particle Inspection (MT) is a non-destructive testing method for identifying surface and slightly subsurface defects in ferromagnetic materials. We have both yoke and bench inspection capabilities to provide maximum flexibility to meet your inspection needs.

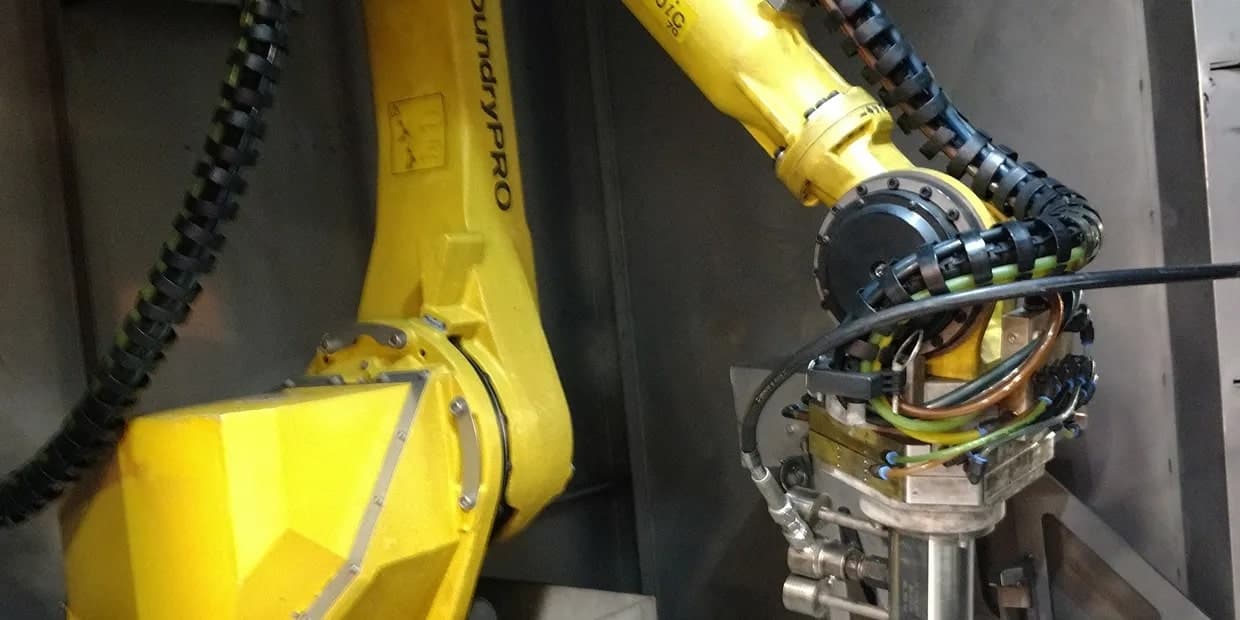

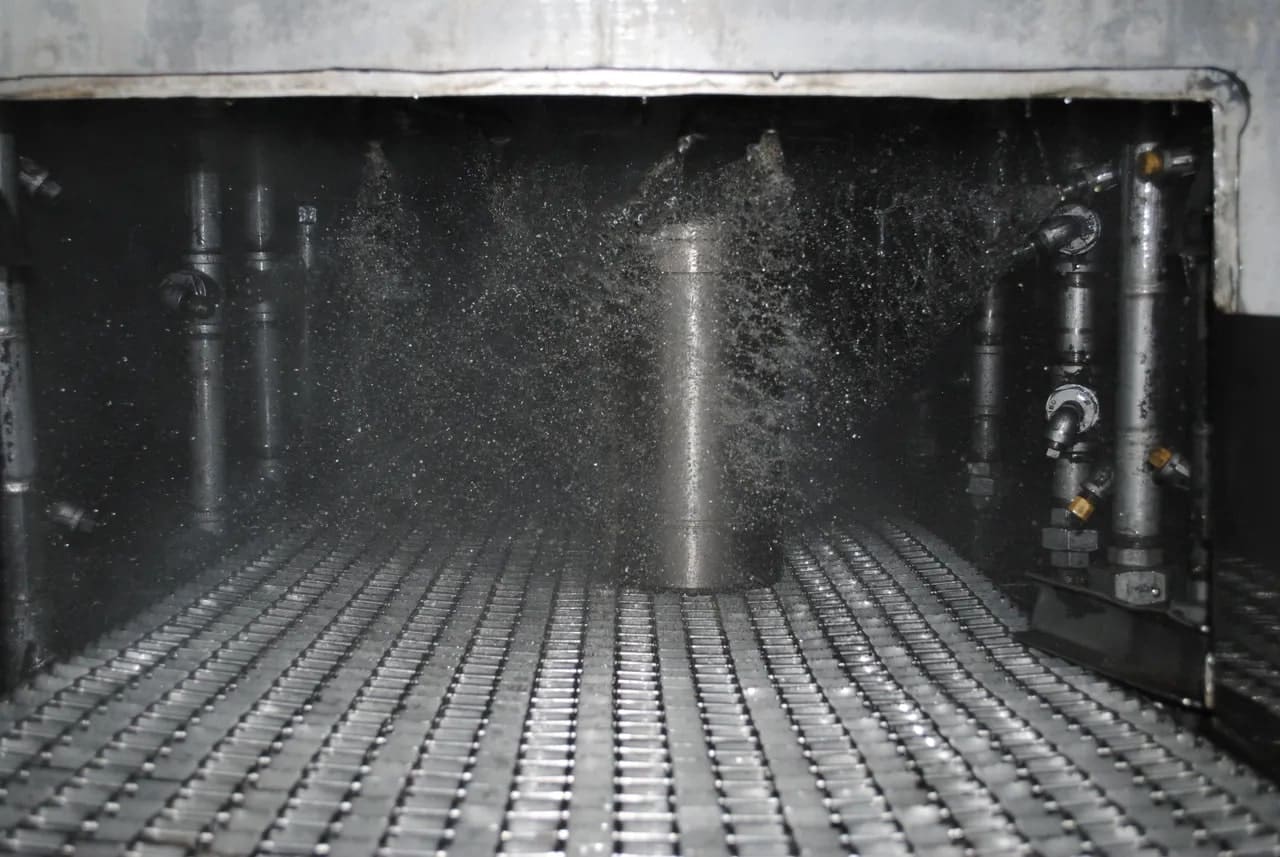

This system uses high-pressure rotary water jets and a six-axis FANUC Foundry Pro robot to remove burrs, chips, and non-parent material from medium-sized, complex machined components.

Our parts cleaning group offers a wide range of equipment and expertise to meet your needs, processing components from 4 ounces to 4,000 pounds.

Everything we do is designed to enhance operational excellence and deliver measurable value for our clients. We are committed to driving innovation, precision, and sustainability in the industries we serve. We strive to be a trusted partner in ensuring quality, safety, and reliability worldwide.

Every day brings new challenges for various industries, and we’re ready to tackle them head-on. Discover more about how we’re overcoming obstacles in our latest projects.

Our specialists are ready to provide fast, reliable solutions tailored to your needs.