Technical Cleanliness Testing Laboratory

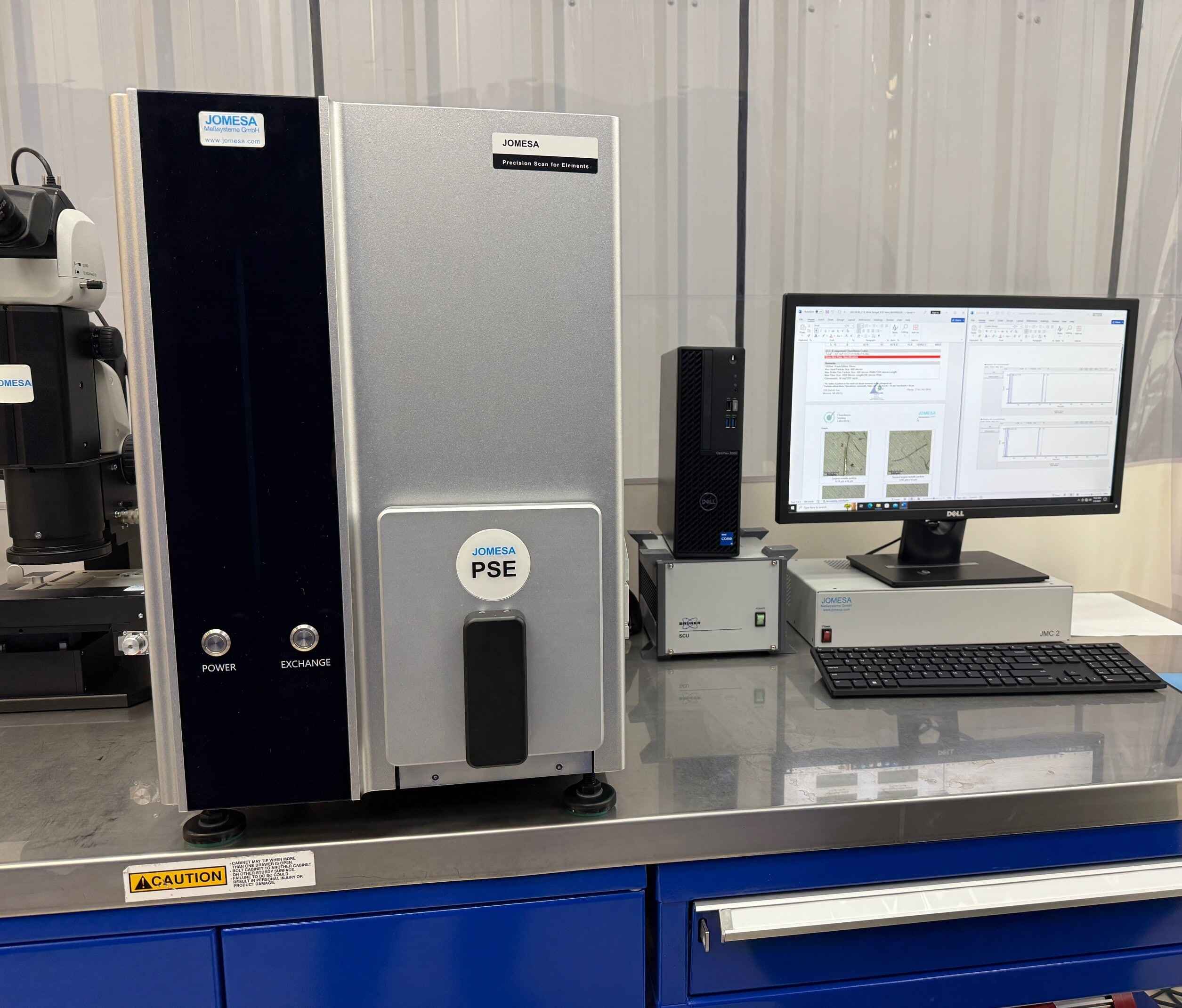

Our technical cleanliness clean room laboratory is outfitted with leading-edge equipment and run by experienced and highly skilled scientists and technicians. We were among the first worldwide to deploy the Jomesa PSE SEM-EDS scanning electron microscope that fully integrates with the Jomesa HFD automated digital particle counting and imaging microscope. This powerful combination provides ISO 16232 and VDA 19 compliant contaminant analysis down to the elemental level. Our lab is capable of testing parts up to 2-tons such as large diesel engine blocks, crankshaft and turbine shafts.

ISO 16232 & VDA 19 Compliant Testing

Our technical cleanliness clean room laboratory is outfitted with leading-edge equipment and run by experienced and highly skilled scientists and technicians.

Capabilities

- ISO 16232 & VDA 19 compliant contaminant analysis.

- Automated particle counting & sizing 5 to 3,000+ microns.

- Identification of particle class (metallic, non-metallic, fiber).

- Gravimetric analysis of contaminants.

- Parts up to 2-tons can be tested in ISO Class 6 like clean room environment.

- Elemental & material analysis using scanning electron microscope.

- Characterization of solid materials including backscattered electron (BSE) imaging to <200 nm.

- Detection and identification of elements from Boron, atomic no. 5 to Americium, atomic no. 95.

- Combine with our precision cleaning capability to meet your specs on-time and in-budget.

Talk to an Expert – Get Answers Now.

Our specialists are ready to provide fast, reliable solutions tailored to your needs.