Liquid Penetrant Inspection Services for Surface Flaw Detection

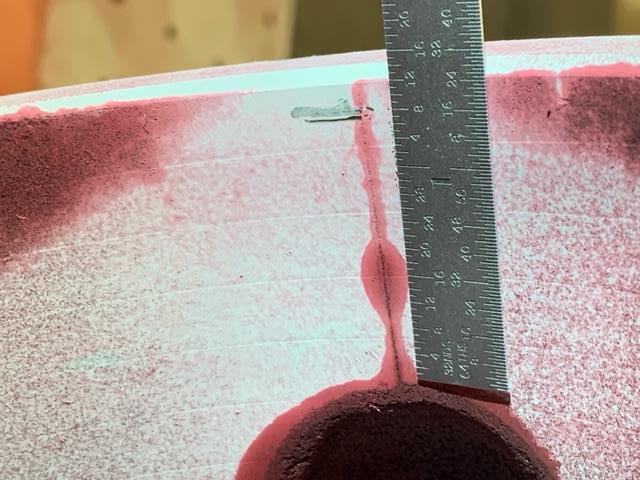

Detect surface-breaking defects with precision using liquid penetrant inspection (LPI). Our certified liquid penetrant testing services support fast, accurate, and cost-effective detection of cracks, porosity, laps, seams, and other discontinuities in non-porous materials.

What Is Liquid Penetrant Testing?

Liquid penetrant testing (PT) is a widely used non-destructive testing (NDT) method that identifies surface-level discontinuities without damaging the material. Also known as a dye penetrant test or penetrant inspection, this method is ideal for detecting flaws in metals, ceramics, plastics, and other non-porous substrates.

Certified Technicians and Inspection Standards

- ASNT Level 3

- ASNT ACCP Level 2

Liquid Penetrant Testing Methods and Capabilities

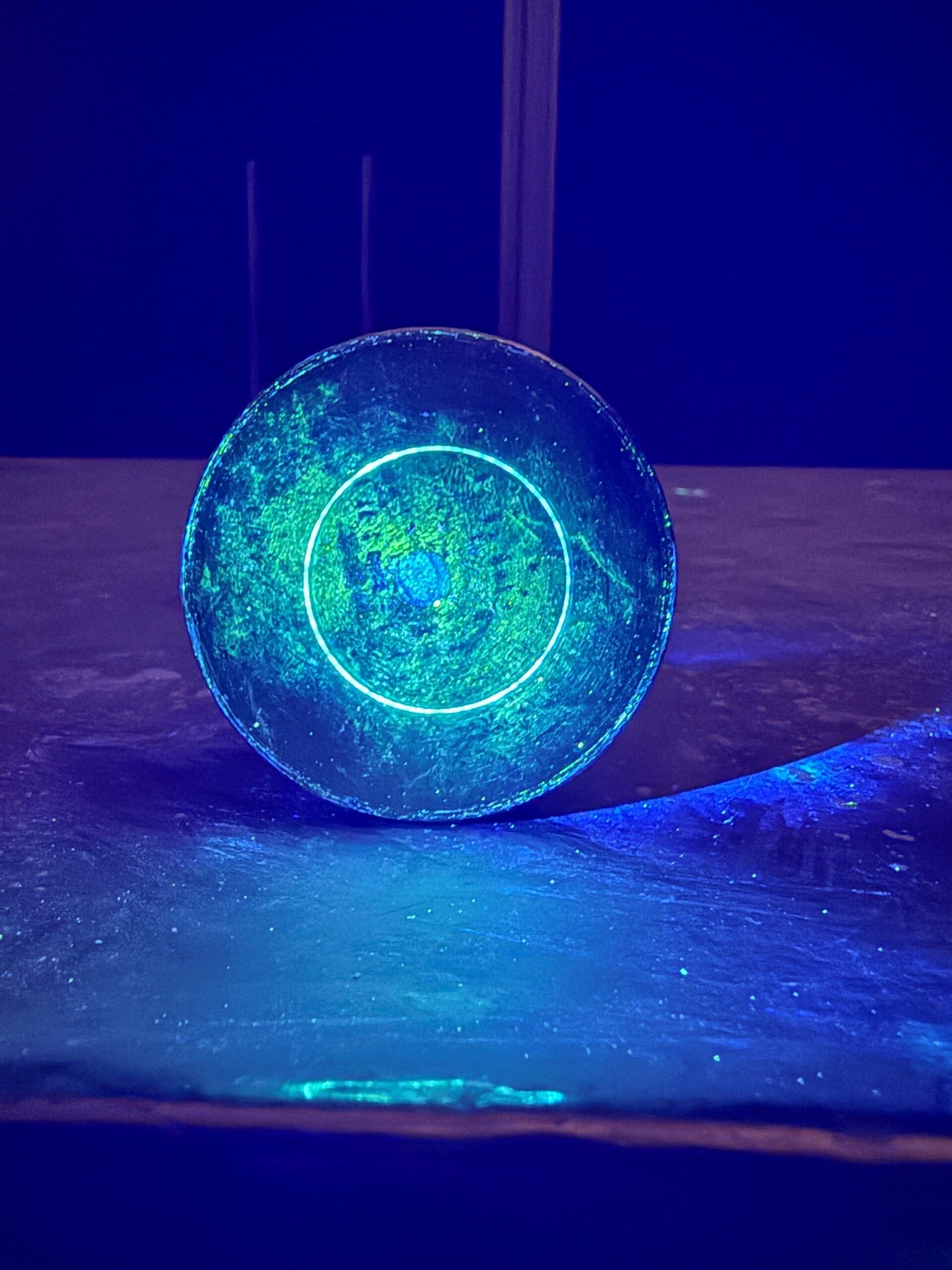

We offer both fluorescent dye penetrant testing and visible penetrant inspection using key setups for flexibility and scalability.

NDT Certifications and Quality Standards

We meet and exceed industry expectations for non-destructive examination (NDE) and penetrant testing.

Benefits of Dye Penetrant Inspection for Critical Components

- Detects surface-breaking defects invisible to the naked eye

- Applicable to a wide range of materials, including castings, welds, and machined parts

- Provides accurate defect location and classification

- Portable testing options are available for field work and large equipment

Talk to a Liquid Penetrant Testing Expert

Need guidance choosing the right penetrant test method for your part or project? Our team of certified NDT specialists is ready to provide expert recommendations and fast turnaround.